[ad_1]

Massachusetts-based 24M Technologies, an MIT spinout that has a partnership agreement with Volkswagen, has unveiled a new recycling process for its SemiSolid EV batteries.

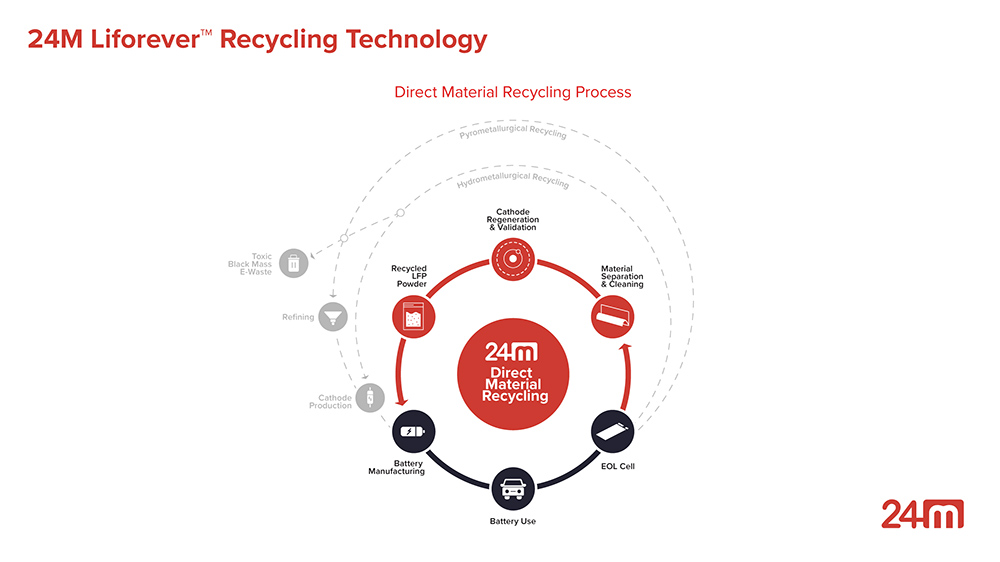

24M says its new Liforever tech, which is built into the company’s battery manufacturing process, offers a way to recycle battery materials like lithium iron phosphate (LFP) more efficiently and cost-effectively.

According to 24M, traditional lithium-ion battery recycling methods, which involve crushing up old batteries into a substance known as black mass, harm the structure of key battery materials, and make recycling less economically viable, especially for cheaper materials like LFP. Usually, only the more expensive metals are salvaged for reuse.

24M’s Liforever process keeps the battery’s active materials in their original form, bypassing the creation of black mass. According to the company, this allows the recycling of all active materials, including those from the anode and cathode. After the materials are recovered, they’re cleaned and, if necessary, re-lithiated to bring them back to their original performance levels.

The company says the Liforever recycling methodology is designed to be compatible with current and anticipated future recycling regulations. 24M’s SemiSolid process is designed to be chemistry-agnostic, so Liforever will support next-gen batteries of all chemistry types.

“Better battery recycling is essential for a sustainable energy future, but the use of binders in conventional cell production has made direct recycling impractical,” said 24M Technologies CEO Naoki Ota. “Liforever solves these challenges by enabling the reuse of nearly every part of the battery cell without requiring the expensive, inefficient and environmentally challenging processes used in conventional cell recycling.”

Source: Electrek

[ad_2]

Source link